“OMG!” is the last thing you want to hear when operating a Mobile Elevating Work Platform (MEWP), Aerial Work Platform (AWP), or boom lift. These machines are powerful, incredibly useful, and potentially dangerous if misused. Tip-overs are among the most serious accidents involving MEWPs, and in most cases, they are entirely preventable.

Here’s how to stay safe and make the most of your equipment.

1. Training comes first. Always

2. Pre-operation checks: start smart

- Operation and safety manuals: Always have the manufacturer's documentation on hand. This will give you critical information on load limits, height restrictions, grade allowances, and more.

- Tire pressure: Check that all tires are properly inflated. Underinflated tires can compromise stability and lead to tip-overs.

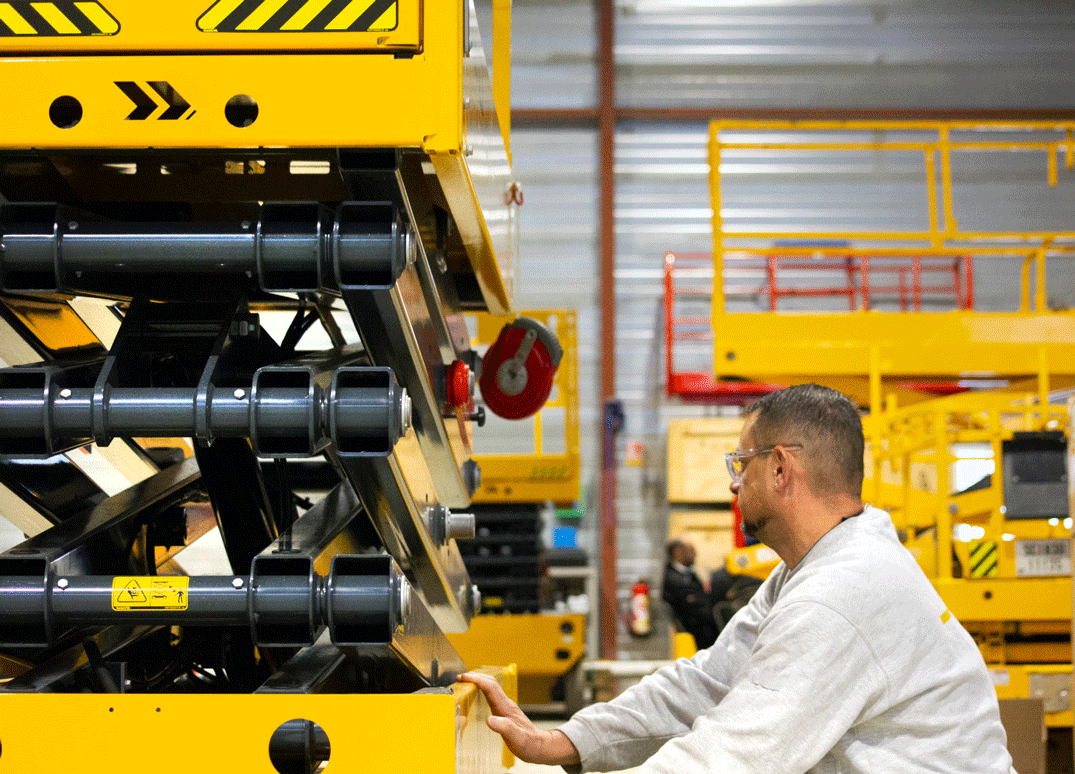

- Hydraulic systems: Inspect all hydraulic hoses and connections for leaks or damage. A failure here could result in sudden loss of control.

3. Best operational practices

- Ground conditions: Only operate on firm, level surfaces. Uneven or soft ground can quickly destabilize your platform.

- Drive cautiously: Avoid potholes, bumps, and sudden movements, especially when elevated.

- Use outriggers or stabilizers: If your machine has them, use them. Ensure they are fully deployed and secure.

- Slopes and grades: Do not exceed the manufacturer’s maximum slope tolerance (typically 5% when elevated). Driving on inclines increases risk significantly.

- Above-Ground surfaces: When working on bridges, trucks, or elevated platforms, always verify load-bearing limits.

- No lifting heavy objects: MEWPs are not cranes. Overloading can quickly lead to a tip-over.

- No tethering: Never attach the platform to another structure. If the MEWP moves unexpectedly, this could cause it to topple.

- Weather awareness: Avoid operating in wind speeds above 45 km/h. Wind can destabilize elevated platforms.

- Know the specs: Always respect manufacturer limits on platform load, height, outreach, and more.

4. Boost operator safety with smart tools

What is MyCompanion?

- How it works: Scan a QR code on the MEWP to access personalized documentation tied to the machine’s serial number.

- Instant information: View operator manuals, maintenance guides, control overview videos, and pre-use checklists—all in one place.

- Interactive learning: Videos and digital content help users understand controls and features easily.

- Safety checklists: Built-in tools for quick visual inspections ensure nothing gets missed.

Extra safety with Sherpal connectivity

- Real-time alerts: Monitor fuel or battery levels, receive safety notifications.

- Weather forecasting: Get local conditions including wind and rain risks, helping operators plan better and act more cautiously.

Stay trained, stay informed, stay safe

Remember: the goal is always to complete the job and come down safely. Tip-overs are no joke, respect the machine, know the risks, and use the tools that help you avoid danger.