What is a scissor lift?

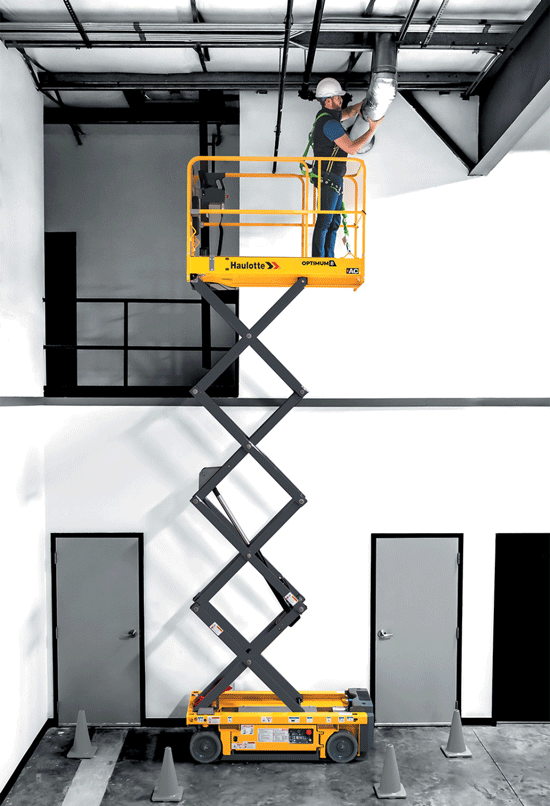

A scissor lift gets its name from the way it elevates. As it rises, the arms tighten and take on the shape of scissors, it exclusively allows vertical elevation. They offer great stability for tasks that do not require outreach and some of them can carry heavier loads (up to 750 kg).

Scissor lifts are divided into 2 categories:

For stabilized floors: Electric scissor lifts operate on all types of stabilized terrains. Very flexible, they offer more compact dimensions than diesel versions and can be used indoors and outdoors, even at full height and without load restrictions.

For all-terrain: With their large platform size, scissor lifts have a higher load capacity than all other types of platforms. They can lift up to 4 people to perform the most demanding tasks. Platform extensions provide additional reach and workspace. The straight-line elevation makes them very easy to handle. Thanks to their high climbing and tilt capacities, all-terrain scissor lifts operate on the most rugged terrains. The stabilizers offer maximum stability. Some of them provide an alternative to diesel for all-terrain work with electric power, offering the advantage of working indoors, emission-free, and silently.

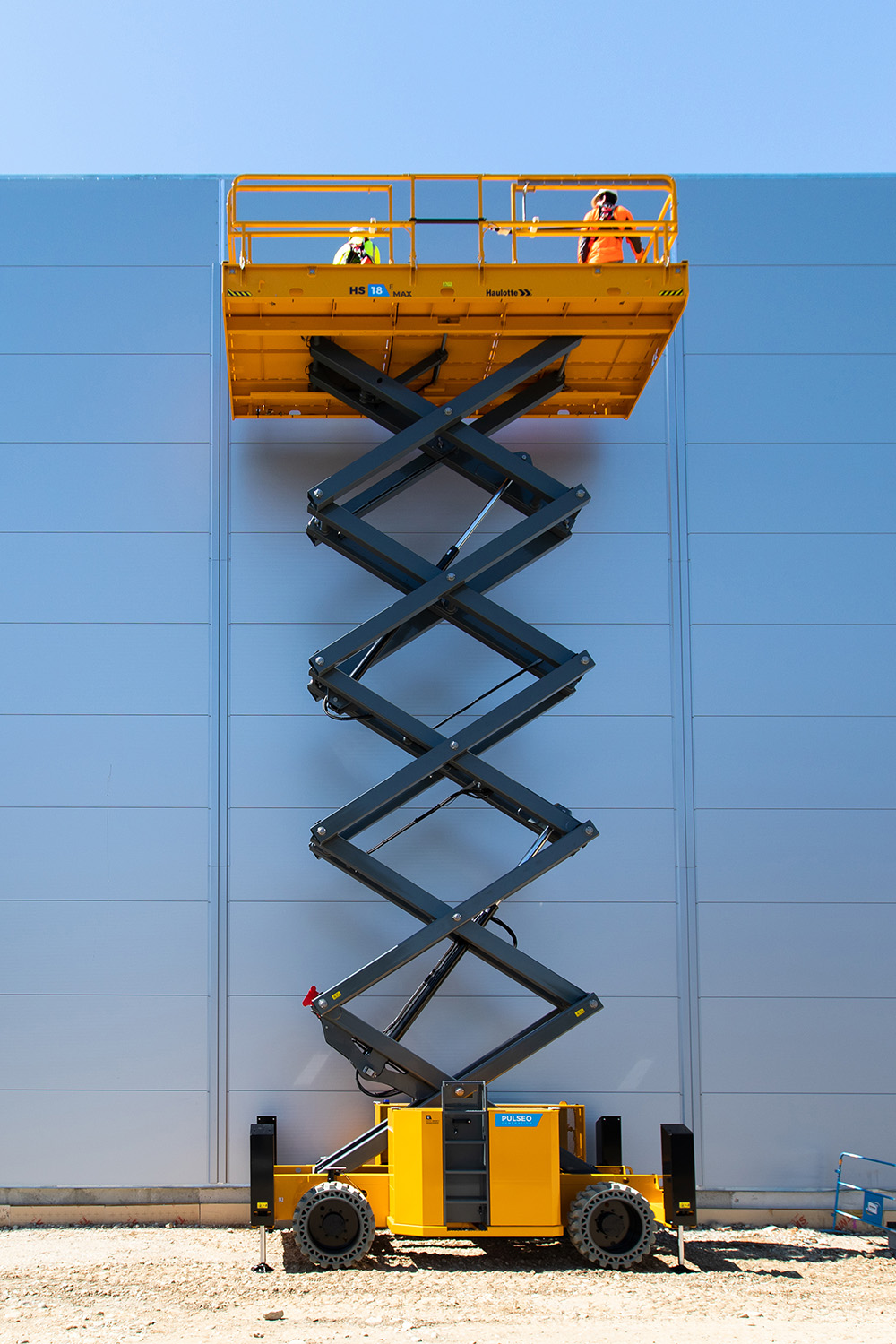

The PULSEO range from Haulotte offers electric scissor lifts from 15 to 18 m of working height, allowing for indoor and outdoor use. Their fully electric architecture provides power and traction equivalent to diesel scissor lifts. These versatile scissor platforms are designed to operate silently in an environmentally friendly manner, for even more opportunities, making them an asset throughout the entire construction project. The “PRO” model features an oscillating axle, a platform with 2 extensions up to 5.80 m in length, and the Activ’Lighting System (lighting device ensuring the operator’s safety during loading and unloading operations). The 18 m HS18E MAX scissor is drivable at full height.

What are the advantages of a scissor lift?

Choosing a scissor lift offers many advantages:

-

Stability: With their unique design, scissor lifts offer excellent stability, even at significant heights. This stability ensures optimal safety for operators.

-

Load capacity: Scissor lifts can support significant loads, making them perfect for tasks requiring the use of heavy equipment.

-

Spacious platform: The large working surface allows multiple operators to work simultaneously.

-

Ease of use: These lifts are easy to use and control, making them accessible even for less experienced operators.

In summary, the scissor lift is a high reach working tool that combines safety, reliability, and productivity.

Scissor lifts are perfectly suited for the following applications:

-

Finish work

-

Main construction (construction and demolition)

-

Maintenance and renovation

-

Green space development

-

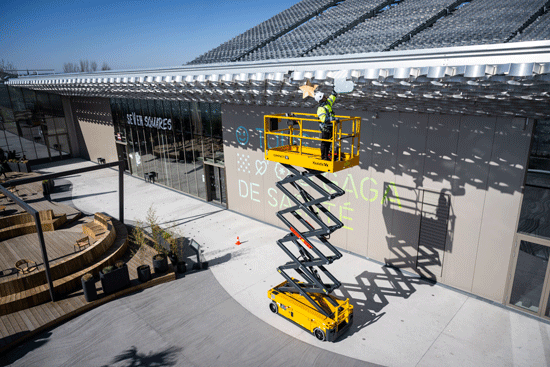

Sporting or event organization

Electric or diesel scissor lift: which type of power source to choose?

The choice between an electric scissor lift and a diesel scissor lift primarily depends on the operating environment, operational constraints, and specific needs of your construction site. Here is a comparison to help you choose:

1. Electric scissor lift

Main features:

- Quiet operation.

- Zero emissions, ideal for indoor or sensitive environments.

- Compact size, often more suitable for confined spaces.

- Rechargeable battery with autonomy depending on intensity of use.

Advantages:

- Indoor or outdoor use (on stabilized ground): Perfect for warehouses, shopping centers, hospitals, or other enclosed spaces where gas emissions and noise are prohibited.

- Environmental friendliness: No fossil fuel.

- Easy maintenance: Fewer mechanical components requiring regular repairs.

- Economy: Reduced operational costs due to the absence of fuel.

Limitations:

- Limited range (about 6-8 hours of continuous use depending on the model).

- Relatively long recharge time.

- Not usable on rough terrain.

Ideal for:

- Indoor work.

- Environments with noise or emissions restrictions.

- Flat and level ground.

2. Diesel scissor lift

Main features:

- Powerful engine, capable of operating in difficult conditions.

- Designed for outdoor use.

- Robust and suitable for rough terrain using all-terrain tires.

Advantages:

- Increased power: Allows working at significant heights and transporting heavier loads.

- Rough terrain: Works well on uneven or sloping ground, using stabilizers or adapted tires.

- Extended autonomy: No recharge constraint, if you have fuel.

Limitations:

- Gas emissions, unsuitable for enclosed or sensitive environments.

- Noisy, which can be inconvenient for work near inhabited areas.

- More expensive maintenance (diesel engine, filters, etc.).

Ideal for:

- Outdoor work.

- Construction sites on difficult terrain.

- Projects that require long work cycles.

It should be noted that there are all-terrain electric scissor lifts that offer power and traction equivalent to diesel lifts. These versatile scissor platforms are designed to operate silently in an environmentally friendly manner, providing even more opportunities for both indoor and outdoor work.

In summary

- Choose an electric lift for indoor work, in enclosed or sensitive areas (low noise, zero emissions), or outdoors on flat ground.

- Opt for a diesel lift if your site is outdoors, on difficult terrain, or for work requiring high power and greater range.

If your needs cover both indoor and outdoor uses, some hybrid lifts (electric + diesel) are available and offer increased versatility, such as the PULSEO range scissor lifts.

Scissor lift: operating mode

The operating mode of a scissor lift is based on a vertical lifting mechanism using a system of crisscrossing supports (hence its name “scissor”) that extend or retract to move the work platform. Here is a detailed guide to its operation:

1. Composition of a scissor lift

A scissor lift consists of several key elements:

-

The work platform: Area where the operator works, equipped with guardrails for safety. It may have extensions to enlarge the work area.

-

The scissor lifting mechanism: Set of articulated metal arms in an X shape that unfolds to raise the platform.

-

The power system:

-

Electric: Powered by a battery, silent and clean.

-

Diesel: Powered by a thermal engine, for outdoor use.

-

-

The chassis: Base of the lift that ensures stability, with stabilizers or potholes (anti-tilt device).

-

The control panel: Located on the platform (and ground control station), it allows control of the lift’s movements.

-

The wheels: Often equipped to adapt to specific terrains (smooth for indoor or all-terrain).

2. Lifting mechanism operation

The mechanism is based on simple principles:

-

Action of hydraulic or electric cylinders:

-

The cylinders apply a force that pushes or pulls the articulated arms, causing them to extend or retract.

-

This movement allows the platform to rise or descend.

-

-

Stability ensured by the crisscrossing supports: The scissor system evenly distributes the loads and ensures the structure’s stability.

3. Operation mode:

Preparation before use:

Visual inspection:

- Check the general condition of the lift (wheels, arms, platform, no hydraulic oil leaks, etc.).

-

Ensure that the load (people and equipment) does not exceed the maximum capacity.

Positioning:

- Place the lift on a flat and solid surface.

- Deploy stabilizers if necessary.

Power supply:

- Charge the battery for electric models.

- Check the fuel level for diesel models.

Movement control:

-

Step onto the platform and use the control panel:

-

Lifting and lowering: Command the activation of the cylinders to raise or lower.

-

Movement: Some lifts can move when raised (depending on the model).

-

-

The controls include safety systems such as:

-

Emergency stop button.

-

Alarm signal for overload or excessive slope.

-

During operation:

-

Keep the platform stable (avoid sudden movements).

-

Follow safety instructions: wear a harness if necessary, avoid overloading, etc.

-

Monitor external conditions (wind, rain).

End of use:

-

Lower the platform completely.

-

Turn off the power.

-

Clean and inspect the equipment before storing it.

4. Safety and precautions

-

Integrated sensors: Lifts are equipped with sensors that stop movements in case of imbalance, overload, or excessive slope.

-

Stabilizers: Automatically or manually deployed to ensure a solid base.

-

Required training: Users must be trained (CACES in France) to operate this type of equipment.

In summary:

A scissor lift operates through a mechanical scissor extension system actuated by cylinders. Easy to use, it requires proper preparation and adherence to safety instructions to ensure effective and safe operation.

Top 3 safety instructions

- Perform a complete visual inspection of the aerial lift platform before use to ensure there is no damage or leaks. Check the oil level, fuel, or battery condition, and tire condition.

- Ensure that the work area is clear and the ground is stable to support the equipment’s weight. Mark the area if necessary.

- Wear a safety harness attached to an anchorage point provided for this purpose on the platform. Also wear any necessary personal protective equipment (helmet, goggles, etc.).

Scissor or articulated boom lift: what are the differences?

Aerial lifts move horizontally and vertically, while scissor lifts can only move up and down. While aerial lifts reach greater vertical heights, scissor lifts have larger platforms with higher weight capacities, allowing them to transport multiple people as well as material loads.

What is the maximum speed of a Haulotte scissor lift?

Haulotte lifts have 2 speed modes

- Minimum mode: 0.5 km/h

- Maximum mode: 5 km/h

However, this criterion is not essential in choosing a scissor lift.

What is the maximum height of a Haulotte scissor lift?

Haulotte scissor lifts range from 8 to 18 m. The straight elevation makes them very easy to maneuver.

The 8 to 14m scissor lifts are electric scissor lifts to operate on all types of stabilized terrains. Very flexible, they offer more compact dimensions than diesel versions, and can be used indoors and outdoors, even at full height and without load restrictions.

The PULESO all-terrain electric scissor lifts range in height from 15 to 18m. With their large platform, scissor lifts have a higher load capacity than all other types of platforms. They can lift up to 4 people to perform the most demanding tasks. Platform extensions provide additional reach and workspace. Thanks to their climbing and tilting capabilities, all-terrain scissor lifts operate on the most rugged terrains. The stabilizers provide maximum stability. PULSEO scissor lifts offer the advantage of working indoors, emission-free, and quietly. Note that the HS18 E MAX scissor lift allows driving at full height. It is designed to maximize productivity and reduce the number of trips between the ground and the work area.

Read also : How to choose a boom lift ?