What is an articulated boom lift?

The articulated boom lift, also known as an articulated boom platform, is lifting equipment with an arm composed of several articulated segments. This elevating platform allows for positioning above obstacles, working at heights, and accessing complex areas, often unreachable with conventional platforms. They can also operate in a smaller space than telescopic booms. With proportional and simultaneous movements, they provide an increased level of stability and safety.

There are two main types:

Electric for stabilized floors: ideal for indoor/outdoor use without emissions. Some models are even electric all-terrain, with the same performance capabilities as diesel machines.

All-terrain diesel: operate in the most rugged terrains because of their exceptional all-terrain capabilities. With proportional and simultaneous movements, they offer an increased level of stability and safety. Note that some models are available with electric powertrains.

Why choose an articulated boom lift?

Articulating booms are particularly popular in the construction, maintenance, and events sectors.

Here’s why:

1. Access to difficult areas

The articulated arm offers significant horizontal outreach, allowing work over or above structures or obstacles (roofs, walls, machines…).

2. Versatility

-

Indoor and outdoor work on stabilized ground: Electric articulating booms are ideal for indoor environments or flat surfaces. They are quiet and emission-free.

-

Rough terrains: Diesel models are designed for outdoor use, even on rough terrains. They are equipped with all-terrain wheels allowing operation on uneven ground.

Finally, electric all-terrain booms offer greater versatility to operate on stabilized or rough terrains, quietly and emission-free, indoors, and outdoors.

3. Working heights and maneuverability

They can reach up to 41 meters, or more depending on the manufacturer, with partial or full arm rotation, increasing their maneuverability in confined spaces.

4. Enhanced safety

Sensors, stabilizers for some of them, guardrails, harnesses, and anchor points ensure maximum protection for operators.

5. Wide range of applications

- Construction: facades, metal structures, …

- Maintenance: industrial equipment maintenance, electrical networks, public lighting, …

- Green spaces: tree pruning, maintenance of large natural areas, …

- Events: installation of temporary facilities, video shooting, …

6. Mobility

Articulating boom lifts allow work in multiple areas without the need for frequent repositioning. Their mobility is a major asset on large construction sites.

In summary: if you need a versatile solution suitable for various environments and situations, the articulated boom is an essential option.

Articulated boom lift diesel or electric: which power source for which needs?

The choice between an electric articulating boom lift and a diesel articulating boom lift depends on the operating environment, operational constraints, and specific needs of your construction site. Some information to help you select the right MEWP:

Diesel articulating boom lift

Advantages::

-

Higher power: suitable for rough terrains and heavier loads.

-

Higher working heights: some models reach up to 40 meters or more.

-

Extended range: ideal for full working days without interruption.

Constraints:

-

Polluting emissions and significant noise

-

Prohibited indoors or in emission-sensitive areas

Recommended use:

-

Outdoor construction sites

-

Outdoor industrial maintenance

-

Work on rough or unstable terrains

Electric articulating boom lift

Advantages:

-

Zero emissions: compliance with environmental standards, perfect for smaller or indoor spaces.

-

Quiet operation: ideal for noise-sensitive sites (hospitals, schools…).

-

Compactness: often more maneuverable with a reduced turning radius.

Constraints:

-

Limited range: requires good recharging management.

-

Less suitable for rough terrains. Haulotte has developed the PULSEO range, an electric, all-terrain boom lift, allowing work without constraints on all types of stabilized or rough terrains.

Recommended use:

-

Work in warehouses, factories, or commercial buildings

-

Indoor maintenance

-

Urban areas with noise or pollution restrictions

Articulated boom lift: how does it work?

1. Mobile chassis (wheels or tracks): Allows the movement of the boom lift on the construction site. Some models are 4×4 for rough terrains.

2. Telescopic articulated arms: These are several segments connected by hydraulic activated articulations (or hinges). They allow vertical movements as well as lateral movements to bypass obstacles.

3. Platform: Secure working space where the operator, equipped with a control panel can operate the boom lift at height.

4. Lower control station: located on a turret, it allows for initial adjustments and is used for emergency interventions.

5. Safety systems: sensors, load limiter, emergency stop, harness, etc.

6. Power system: electric, diesel, or hybrid depending on the model.

The boom extends using a hydraulic system for smooth ascent, obstacle bypass, and precise positioning.

How to use an articulated boom lift safely?

The safe use of an articulated boom lift is based on 5 essential pillars:

1. Preliminary checks

Visual inspection

-

Check the general condition of the lift (arms, tires, cables, basket…)

-

Look for oil leaks or mechanical damage

-

Ensure that safety devices are in place (guardrails, harness, emergency stop switch…)

Functional checks

-

Test controls (up, down, outreach, rotation)

-

Check alarms and audible warnings

-

Test the emergency stop button

2. Training and authorization

-

The operator must be trained and authorized with CACES® R486 (type B) in France or hold the license issued by IPAF (PAL card: Powered Access License). The IPAF PAL card is the most recognized training certificate internationally. This training must be updated every five years.

-

They must know the model being used, its limitations, and the manufacturer’s instructions

-

Wear mandatory personal protective equipment (PPE):

-

Harness with short lanyard attached to the anchorage point

-

Helmet, gloves, safety shoes, vest

-

3. Site preparation

- Outline the work area (barriers, tape, warning signs)

-

Ensure ground safety (no excessive slope, stabilized ground, no hidden obstacles)

-

Check the environment:

-

Nearby power lines (respect safety distances)

-

Vehicle or pedestrian traffic

-

Weather conditions (no strong wind or heavy rain)

-

4. Working at height

-

Ascend slowly and in stages

-

Never exceed the maximum allowed load (indicated on the plate)

-

Always stay inside the basket, do not climb on the guardrails

-

Do not drive the lift in an elevated position, unless the model is designed for this purpose

-

Do not use the lift as a crane or to lift suspended loads

5. Managing emergency situations

-

Know how to use the emergency descent device (often operable from the ground)

-

Maintain contact with a trained person on the ground to intervene if necessary

-

Have a phone or quick communication method available

How to choose the right articulated boom lift?

Here are the key criteria:

- Working height: Working height is an important criterion to consider when choosing an articulated boom lift. Make sure to select a lift that can reach the necessary height for your project.

- Horizontal outreach: Horizontal outreach is also a significant factor. The greater the horizontal outreach, the more the lift can move laterally to access different areas without needing to be repositioned.

- Load capacity: Load capacity is essential for determining the amount of materials and the number of people the lift can carry. Make sure to choose a lift that can support the necessary weight for your project.

How to transport an articulated boom lift?

Transporting an articulating boom lift safely requires good logistical preparation and compliance with the manufacturer’s instructions as well as safety regulations.

Before transporting a boom lift, always refer to the Operator’s Manual specific to the model for transport instructions. If possible, transport the boom lift with its basket placed horizontally on the trailer floor.

1. Preparation in advance

Check the dimensions and weight

- Length, width, height when folded

- Total weight of the machine (indicated on the manufacturer’s plate)

- Flatbed truck, equipment trailer, or suitable semi-trailer

- Check the load capacity and access ramps are compatible with the weight of the boom lift

2. Prepare the boom lift for transport

Steps to follow:

- Fold the articulated arm completely and lock the sections if necessary

- Lower the basket to the lowest level

- Turn off the engine (and disconnect batteries if required)

- Check the brakes (self-propelled models often have a parking brake)

3. Load the boom lift onto the vehicle

Procedure:

- Ascend slowly using non-slip ramps

- A ground guide can assist with alignment

- Ensure you center the boom lift on the truck or trailer

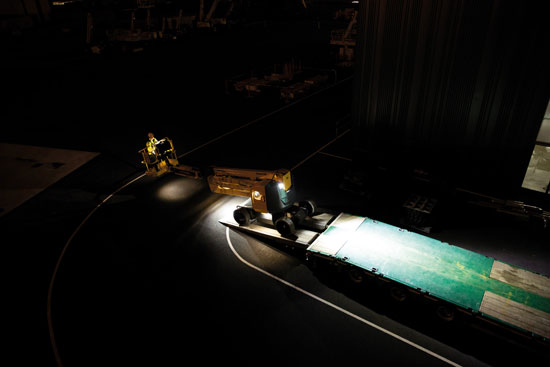

Boom lift loading and unloading often occur at the beginning or end of the day. To increase safety during these delicate operations, Haulotte has created the Haulotte Activ’Lighting System. The system ensures the driver’s safety during loading or unloading operations, composed of optimally placed LED lights, it perfectly illuminates the basket, controls, and the area around the machine.

4. Securing and safety

Securing elements:

- Reinforced ratchet straps or tension chains

- Anchor points provided on the chassis

It is imperative to:

- Secure both front AND rear

- Chock the wheels with wheel chocks

- Check the securing after a few kilometers

5. Compliance with regulations and safe unloading

- Compliance with the Highway Code (weight, height, width)

- Oversized load permit if the boom lift exceeds standard dimensions

- Signaling devices (lights, reflective panels, beacons if necessary)

- Choose a flat and clear area

- Remove restraints only after positioning the ramps

- Descend slowly and smoothly

What is the maximum speed of an articulated Haulotte boom lift?

- When elevated, movements are often automatically limited to a very slow speed or disabled for safety reasons.

- Moving at height is sometimes possible on specific models, at very low speed (often < 1 km/h), and on flat ground only.

To find out the exact speed of a specific model, it is recommended to consult:

-

The Haulotte user manual for the relevant model

-

The official technical data sheet on one of the Haulotte websites

What is the maximum height of a Haulotte articulated boom lift?

The maximum height of a Haulotte articulating boom lift depends on the model. The Haulotte range covers a wide range of working heights, ranging from 12 meters to over 41 meters. Please note:

- Working height: maximum height reachable by the operator’s hands (basket included). Generally, it is 2 meters higher than the height of the basket floor.

- Floor height (or platform height): the height at which the bottom of the basket is located.

The articulating boom lift is the essential tool for all your work at height requiring versatility, safety, and mobility. Diesel, electric, or hybrid, each model meets a specific need. By understanding your site constraints well, you will make an informed, safe… and profitable choice.

Read also : How to choose a boom lift ?